What led you to become an electronic engineer?

As a child, I was fascinated by the fairy electricity. I was amazed by this science, almost magical, that allowed us to control objects remotely, by simply pressing a button.

I was naturally inclined toward technical studies, and I quickly developed a passion for electronics, electromagnetism, and astronomy.

Can you describe the building blocks of your career?

During my career, I had the chance to always work on technological innovations: radiotelephony in the 80s, digital transmission in the 90s, Electromagnetic Compatibility in the 2k and, the LED lightings for automotive from 2012.

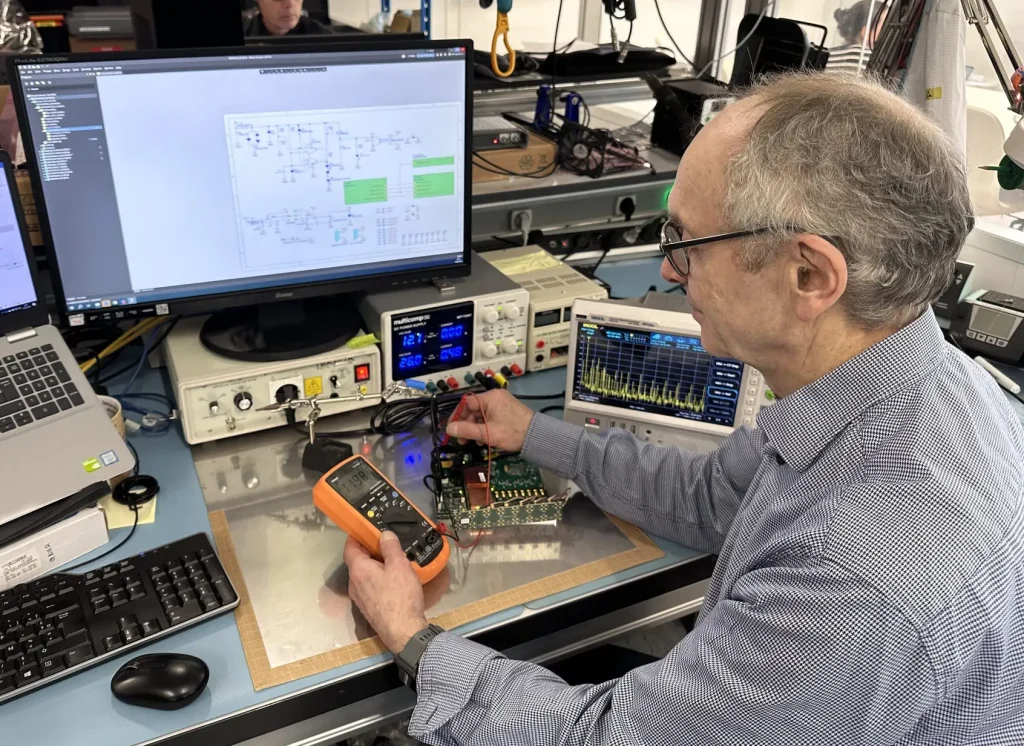

In this journey, the physics of systems held my attention. Many times, my experience has taught me that, if an electronic board works perfectly in the R&D environment, it sometimes reveals weaknesses once placed in the industrial environment.

Industry Applications:

How can industrial applications affect the electromagnetic field ?

On an industrial site, the electromagnetic field changes because of the electronic equipment implemented. For example, the remote computers controlling the equipment, the industrial machinery operating nearby and/or local communication network generate their own electromagnetic disturbances.

And those application scenarios and invisible disturbances are almost impossible to predict before implementation.

How about electromagnetic disturbances?

To ensure that our devices do not emit excessive electromagnetic radiation and are immune to external electromagnetic interference, we design them in accordance with EMC principles and standards.

EMC, short for “Electromagnetic compatibility”, is a set of requirements to make various electrical and electronic equipment compatible so that they operate properly without causing or experiencing electromagnetic interference.

How do you ensure TPAC's devices' optimal performance on the field?

Our products at TPAC often need to operate in harsh industrial environments, alongside welding robots, embedded in inspection vehicles, etc. I work closely with mechatronic designers to prevent countless cases of electromagnetic disturbances.

I then bring my expertise to place the functions on an electronic board, to add the right protections against disturbances conducted on electrical connections, to connect certain layers of the printed circuit board, and possibly add shielding against radiated disturbances.