What Is a Linear Probe in Ultrasonic Testing?

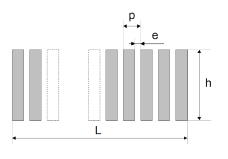

A linear probe has its active area divided into several elements in one direction, as illustrated below.

Each element can be addressed separately to generate the appropriate ultrasonic beam and imaging method.

In Non-Destructive Testing (NDT), this configuration allows inspectors to precisely control beam steering and focusing without moving the probe in the plane of incidence.

What Are the Advantages of Linear Probes?

Linear array probes offer several key benefits in Non-Destructive Testing (NDT):

- Electronic scanning, steering, and focusing : the ultrasonic beam can be controlled without moving the probe in the plane of incidence, enabling faster and more flexible inspections.

- Time efficiency : replaces multiple conventional probes with different angles and focal distances.

- Advanced imaging : supports both standard and fast-imaging techniques for detailed defect detection.

- Large-area coverage : when combined with mechanical scanning in the transverse direction, they can inspect large surfaces and volumes efficiently.

TPAC equipment enables the full capability of linear array probes, including Phased Array Ultrasonic Testing (PAUT) techniques and advanced methods such as Total Focusing Method (TFM), Plane Wave Imaging (PWI), and Partial Coherence Imaging (PCI).

All TPAC systems are fully compatible with encoded scanning and raw data storage.

What Parameters Define a Linear Probe?

Several parameters determine the performance of a linear probe in Non-Destructive Testing (NDT):

- Number of elements : typically 32, 64, or 128 in NDT applications, though other configurations are possible.

- Frequency range : from 0.5 MHz to 15 MHz, chosen according to penetration depth and resolution requirements.

- Pitch (p) : the distance between adjacent elements along the array.

- Elevation (h) : the size of each element in the transverse direction.

Other important factors include:

- Housing shape and materials for durability and ergonomics.

- Cable length and connector type to ensure proper integration with the inspection system.

TPAC has extensive experience in designing phased array probes for a wide range of applications, and can assist you in defining the optimal configuration for your inspection needs.

Our systems are supplied with a standard Ipex connector, and we offer multiple types of adaptors to interface with other connector types when required.

What Are the Typical Using Conditions for a Linear Probe?

Linear array probes can be used in multiple inspection configurations, making them compatible with most Non-Destructive Testing (NDT) applications:

- Direct contact : for quick and straightforward inspections.

- Contact through a wedge : to adapt beam angle, work with shear waves, or prevent probe abrasion.

- Immersion testing : for precision inspections.

They support various inspection modes:

- Pulse-echo (PE) : using a single probe to send and receive the signal.

- Through-transmission (TT) : transmitting the ultrasonic wave through the material from one probe to another.

- Dual linear array (DLA) : using two arrays for enhanced detection capabilities.

TPAC instruments and software are designed to take full advantage of all these modes, ensuring maximum flexibility in inspection strategies.

How Flexible Is the Design of a Linear Array Probe?

By adjusting the key parameters above, linear array probes can be configured for a very wide range of capabilities.

- Some probes can be as long as 40 cm for fast scanning of wide and thick parts.

- Others can be as small as a few millimeters to fit into tight spaces, such as between rotor blades.

TPAC works in close collaboration with major phased array probe manufacturers, guiding clients toward the right probe across this wide range of possibilities, from standard designs to fully customized solutions.

For Which Applications Are Linear Probes Used in NDT?

Linear probes can meet the requirements of most Non-Destructive Testing (NDT) applications, including:

- Weld inspection : detection of cracks, porosity, and lack of fusion in joints.

- Corrosion mapping : accurate measurement of wall thickness in pipelines, tanks, and structural components.

- Composite inspection : identification of delaminations, voids, and impact damage in aerospace or automotive parts.

- Forged parts inspection : detection of internal flaws in large or complex geometries.

- Inline manufacturing control : rapid inspection integrated directly into production lines.

They are also compatible with automated and semi-automated inspection systems, such as crawlers or robotic arms.

TPAC Explorer and Explorer Max systems, along with their associated software, are ready-to-use for most of these applications, ensuring efficient deployment and reliable inspection results.

What Is the Difference Between Linear and Curved Array Probes?

Curved array probes have a circular shape in the plane of incidence, typically concave.

This geometry makes them particularly useful for inspecting cylindrical parts, such as tubes and bars.

They can also be used for the inspection of aeronautical components with curved radii, where the probe’s shape allows for better surface contact and optimized ultrasonic beam transmission.

What Other Types of Array Probes Exist Besides Linear and Curved Arrays?

Linear and curved array probes can electronically control the ultrasonic beam in one direction.

In contrast, matrix array probes have a two-dimensional (2D) element pattern, enabling full three-dimensional (3D) beam steering for volumetric inspections.

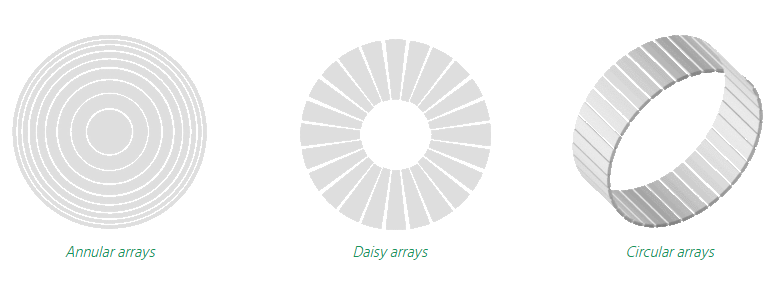

Other specialized probe designs also exist for specific applications, including:

- Daisy arrays

- Annular arrays

- Circular arrays

What Is the TPAC Bonus?

In addition to its expertise in probe design and strong network of major manufacturers, TPAC was an early adopter of conformable wedges for phased-array probes.

This type of wedge enables the inspection of parts with irregular or even unknown surfaces, while maintaining a consistent ultrasonic beam inside the material.

To fully exploit the advantages of these wedges, TPAC’s scientific experts developed real-time adaptive algorithms embedded in our software.

These algorithms allow live adjustment of inspection parameters for such complex surfaces.

TPAC was the first to bring this method into field operations, using the Explorer Max system and Prelude 5 software to address CSC inspection challenges in French nuclear power plants.

Frequently Asked Questions

Can linear array probes be combined with other ultrasonic probe types in a single inspection?

Yes. In some advanced inspection setups, linear arrays can be combined with other probe geometries, such as matrix or curved arrays, to optimize coverage and resolution across complex components.

Are conformable wedges only useful for irregular surfaces?

While they are especially valuable for irregular or unknown surfaces, conformable wedges can also improve coupling and beam consistency on slightly curved or challenging materials.

Can linear array probes operate in through-transmission mode for thick materials?

Yes. When used in a pair, linear array probes can perform through-transmission inspections, which can be advantageous for detecting certain types of defects in thick or attenuative materials.

How does TPAC ensure that a custom probe design meets inspection standards?

TPAC’s engineering process takes into account the inspection objective, applicable industry standards, and environmental constraints. Prototypes can be validated in lab conditions before deployment in the field.